TATA TISCON SD 550D

THE BAR THAT BENDS, NOT BREAKS

Tata Tiscon – The Reliable Rebar

Introducing Tata Tiscon SD 550D, the most advanced Thermo-Mechanically Treated (TMT) rebar from Tata Steel, India’s first GreenPro-certified rebar brand. With a legacy of innovation from Fe415 to Fe500D to Fe550D, Tata Tiscon sets industry benchmarks with superior ductility and strength.

A CHOICE OF PROFESSIONALS

UNMATCHED STRENGTH & DUCTILITY

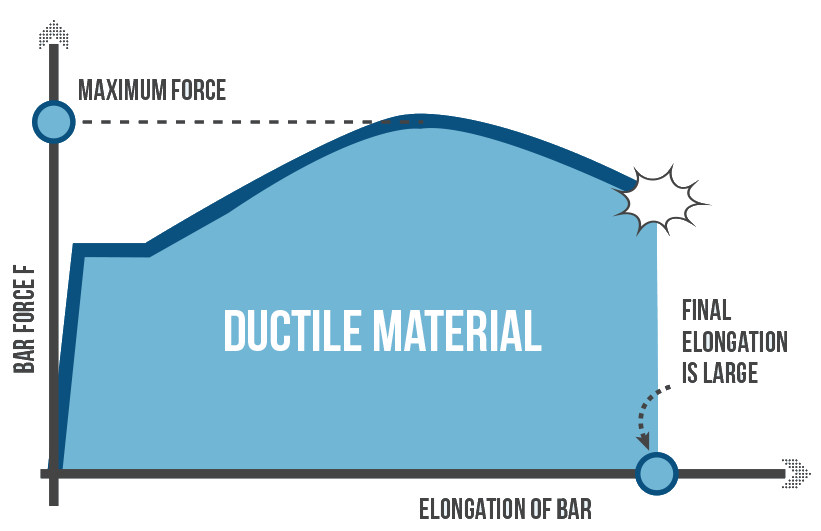

Construction projects demand rebars that can withstand extreme stress and dynamic loads. Tata Tiscon SD 550D is specifically designed with a higher UTS/YS ratio, meaning it maintains structural integrity even under seismic activity and excessive force.

ENHANCED SAFETY IN EARTHQUAKE-PRONE ZONES

With 55% of India's land vulnerable to earthquakes, structural strength isn’t just a

preference—it’s a necessity. Conforming to IS 13920:2016 seismic design standards, Tata Tiscon

SD 550D offers:

High Toughness (UTS/YS > 1.15) – Ensures superior shock absorption during seismic

activity.

High Total & Uniform Elongation – Prevents sudden collapse, allowing structures to

flex instead

of fail.

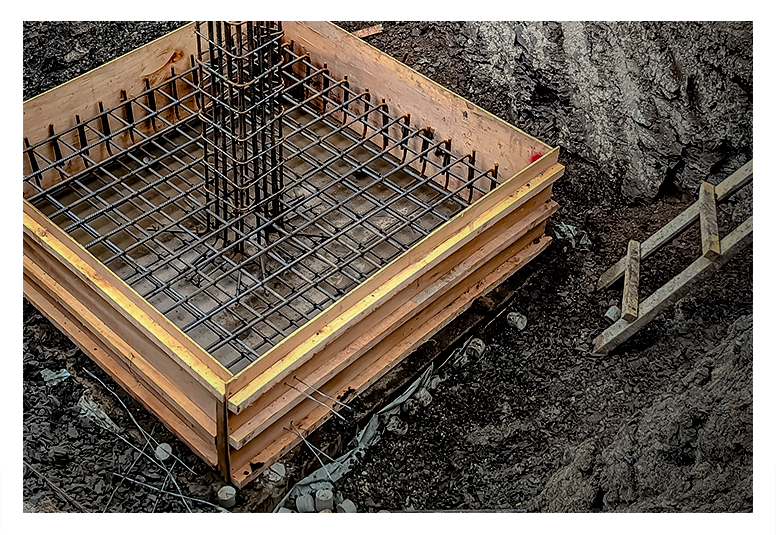

PRECISION-CONTROLLED MANUFACTURING PROCESS

Unlike secondary manufacturing methods, Tata Tiscon SD 550D is produced using the controlled

primary manufacturing route, ensuring:

Virgin Iron Ore-Based Composition – Purity, strength, and longevity.

Optimised TMT Macrostructure – Greater reliability compared to secondary rebar

manufacturers.

Consistent Batch Quality – Large-scale batch uniformity prevents discrepancies in

structural

properties.

PROTECT STRUCTURES IN EARTHQUAKES

During seismic events, structures face stress beyond their Yield Strength (YS). Standard rebars risk sudden failure when stress exceeds the Ultimate Tensile Strength (UTS). Tata Tiscon SD 550D rebars feature a higher UTS/YS ratio, allowing greater plastic deformation without structural collapse. This ensures superior earthquake resistance & longevity.

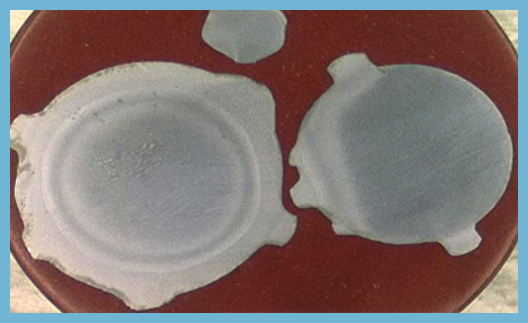

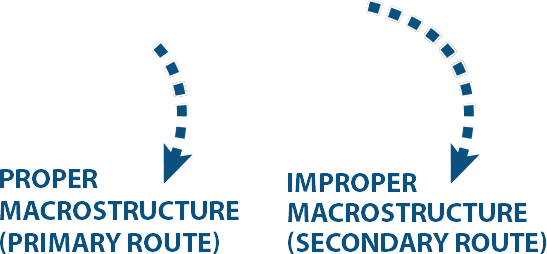

SUPERIOR MANUFACTURING PROCESS

Superior TMT quality begins with a superior manufacturing route.

Controlled route vs Uncontrolled route

Believing that all deformed bars are TMT, the customer selects a rebar based on its surface appearance and other non-functional features.

TATA TISCON SD 550D CRS

CORROSION RESISTANT REBARS

Tata Tiscon 550D Corrosion Resistant Rebars fight salinity in the air, sea-water, groundwater, moisture and acid particles in the air, protecting the life of your structures. These are best suited to resist both corrosion and damages caused by earthquakes. Add to that the legacy of the Tata group. Unshakeable, compared to ordinary rebars which have a shorter life span, leading to corrosion and decay.

MARQUEE PROJECTS USING TATA TISCON 550D CRS REBARS

Dholera

Semiconductor

Project

Manora

MLA Hostel

Bandra Sewage

Treatment Plant

Agratas Battery

Manufacturing

Facility

TECHNICAL SPECIFICATIONS

Tata TISCON SD 550D: Mechanical Properties

Fe 550

Fe 550D

Fe 550

Tata TISCON SD 550D: Chemical Properties

Fe 550D

550SD

Super Ductile

Tata TISCON SD 550D CRS: Mechanical Properties

Fe 550

Fe 550D

Fe 550

Tata TISCON SD 550D CRS : Chemical Properties

(Cu + Cr + Mo + P + Ni) (Min)

AVAILABILITY

Tata Tiscon 36/40mm Rebars

Tata Steel offers high grade rebars for heavy construction like Metro Rail, Tunnels, Bridges etc.

Customized length rebars of Tata Tiscon

Available in lengths of 7.5, 8, 8.5, 9, 9.5, 10, 10.5, 11 and 11.5 meters. Use of these rebars helps in steel optimisation and wastage reduction resulting in huge savings.

Additional Offerings

-

Customised Length Rebars (7.5m to 11.5m) to reduce waste & optimise costs.

-

Tata Tiscon 36/40mm Rebars.

Connect with US

Reach Us

Commercial Head Quarter

Tata Centre 43, Jawaharlal Nehru Road

Kolkata - 700 071

Contact No

Toll Free No. 0124-6934550

Email Address

lpeast@tatasteel.com (East)

lpwest@tatasteel.com (West)

lpsouth@tatasteel.com (South)

lpnorth@tatasteel.com (North)